Replacing the Archimedes Battery Holder

The Archimedes A300 and A400 series use an off board design for battery storage within the Archimedes' case which helps to mitigate damage to the Archimedes when battery leakage occurs.

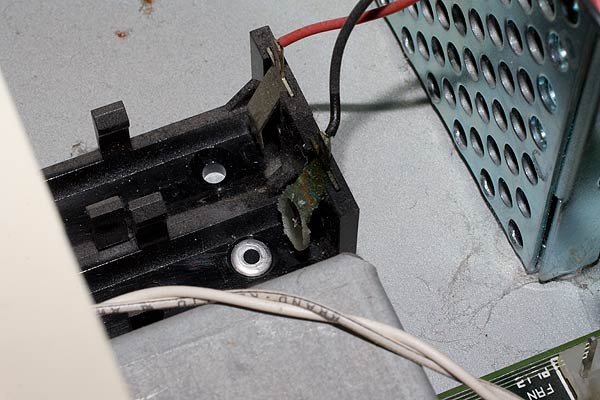

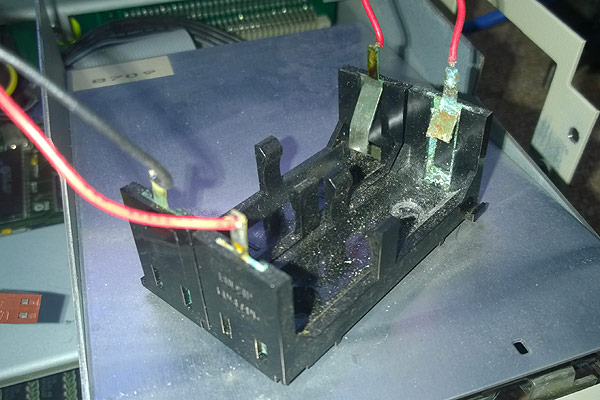

However, battery leakage can damage the battery holders themselves which means that the battery holder must be replaced. You can see in the photo below, the negative terminal has experienced damage due to alkali leakage from a battery. This damage leads to metal fatigue and eventual failure as the battery contacts become brittle and eventually snap.

At the time of writing in June 2015, the original battery holders are still manufactured and therefore, any damage can be repaired by replacing the holder with a brand new OEM part.

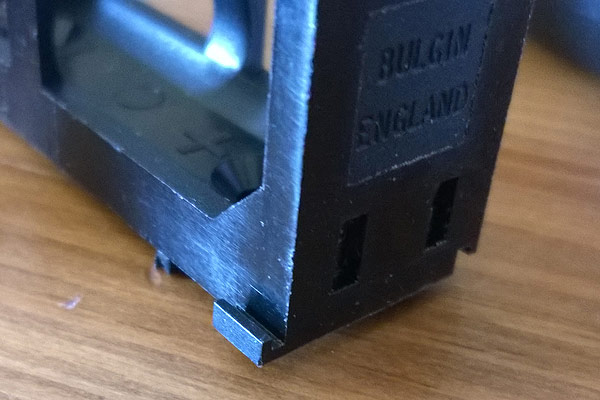

The battery holders are manufactured by Bulgin whose parent companies head office is still in Cambridge. The holders are actually single AA holders however they are designed to be modular and interlock with each other in order to allow the holders to be expanded to provide the capacity needed for a specific project.

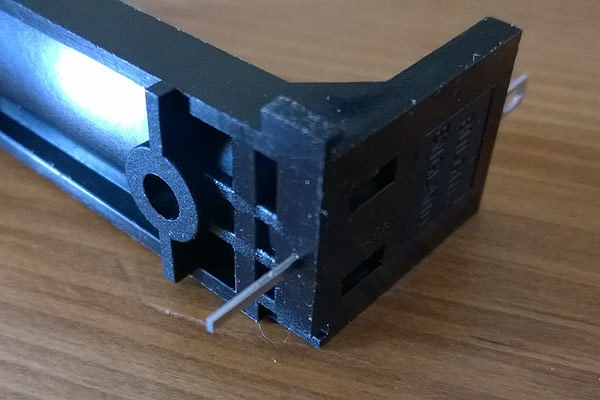

I purchased two Bulgin BX0035 battery holders from RS components. They are produced to be connected either in a through-hole PCB configuration or as they are configured within an Archimedes using the upper tabs.

The through hole tails can simply be snipped off in order to allow them to be fitted to the Archimedes.

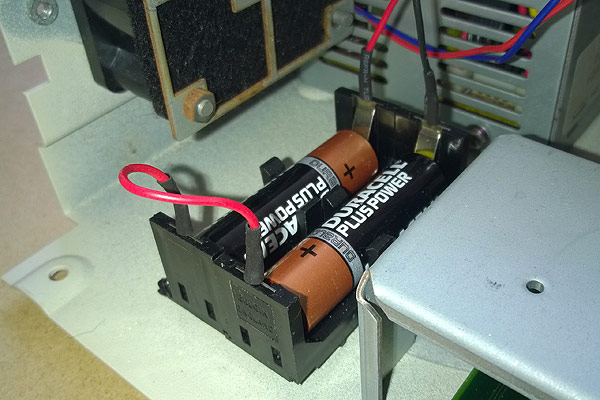

You can see in the next photo how the battery holders interlock with the lugs as shown when the battery holder is upright.

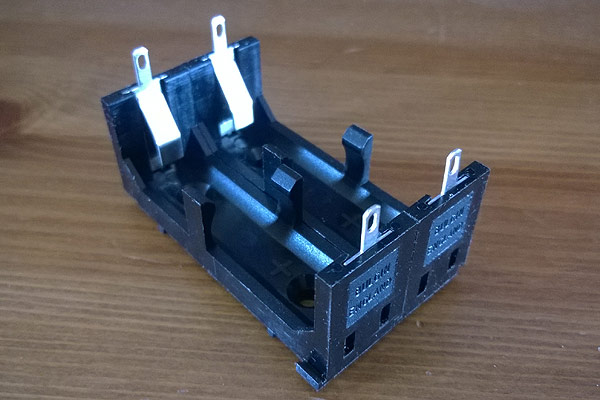

The next photo shows how two battery holders are attached to each other, ready for fitting into an Acorn Archimedes A300 or A400 series machine. The mouldings have simple interlocking tabs which allow any number of these AA battery holders to be connected together.

Once the battery holders are ready to be fitted, the original rivets must be drilled out to allow removal of the original battery holders.

After removing the holders, you can clearly see the full extent of the damage to the contacts in the photo below where one of them has snapped off due to metal fatigue as a result of corrosion from the battery leakage.

With the new holders ready to be fitted, they must be linked and then pop-riveted into place ensuring the batteries will be held securely in the Archimedes.

All that remains is for the wiring and connectors to be re-soldered to the newly fitted battery holders. I re-used the original wires from the existing battery holders after cleaning and trimming them to ensure there was no corrosion ensuring the most original restoration possible.

Finally, I placed a small amount of heat shrink on the wires to insulate the tabs once they were all soldered into place. Remember to keep the heatshrink out of the way when soldering but don't forget that it must be over the wires before you finish your solder work. Once everything is soldered up, a hot air gun applied to the heatshrink makes a really neat job of it!

I'm happy to report the Archimedes A310 this repair was carried out on is now storing the CMOS settings and keeping time when powered off perfectly and you can't even tell that the repair has been made thanks to the use of original parts.

Translate this site

Acorn BBC Archimedes A310

A310 maintenance

Other maintenance resources

Acorn Archimedes A400/1

A400/1 maintenance

Other maintenance resources

IconBar posts

News

- RISC OS continues to grow on GitHub

- Archive magazine updates

- Wakefield 2022 will go ahead on Saturday 21st May

- Drag'n'Drop 11i2 edition reviewed

- RISCOSbits releases some more risque hardware

Forums

- RISCOSbits releases some more risque hardware

- Is BASIC still useful for coding?

- Is BASIC still useful for coding?

- Three RISC OS Show dates for your 2022 diary

- Iris Web Browser receives January update

provided courtesy of The IconBar